Products:

The Omni Arm

The Omni Arm was invented in 1989 by President Jeffrey Barkes. It replicates the dexterity of the human forearm. Raising, lowering, rotating, and articulating motions are controllable in thousandths of an inch. The Omni Arm removes and installs landing gear in just minutes. The Unit's hydraulic system incorporates an over-weight and over-travel safety trip to prevent damage to the aircraft, landing gear, Omni Arm, and personnel. There are currently over 100 Omni Arms in service with major aircraft manufacturers, MRO's, Commercial Airlines, U.S. & Foreign Military.

Additional Benefits:

Additional Benefits:

|

|

Currently Manufacturing Models Servicing:

|

|

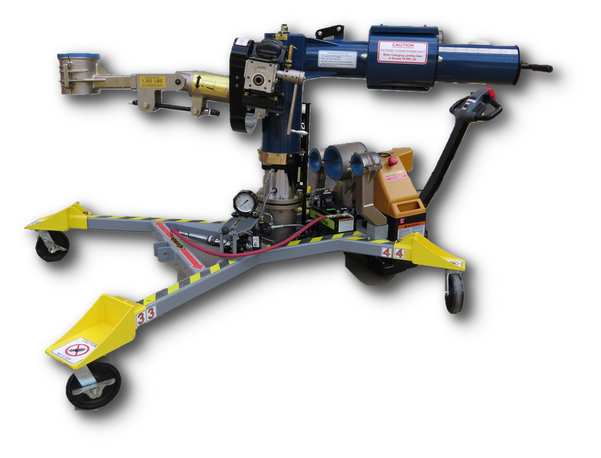

Omni Arm Model NBH

For Servicing A320 & A220 (CSeries)

1,300 Lb. Cap

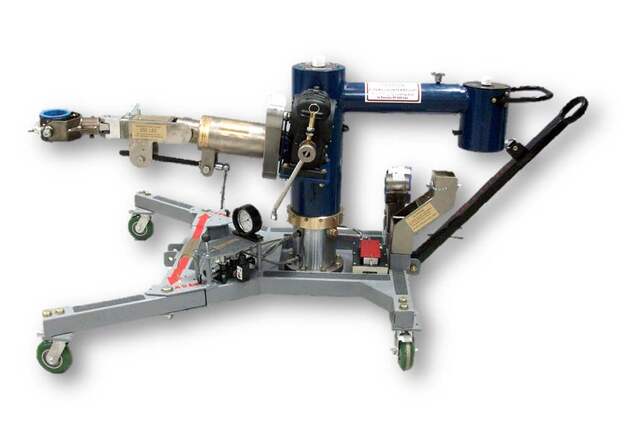

Omni Arm Model NB-800

For Servicing B 717, B 727, B 737 Classic, & B 727NG

1,000 Lb. Capacity

Omni Arm Model EL-MO

Specialty Model for Aircraft Manufacturer

1,500 Lb. Capacity

Omni Arm Model NBM

For Servicing C-130 & A-10 Wart Hog

680 Lb. Capacity

Omni Arm Model RA

For Servicing Regional Jets

550 Lb. Capacity

The Universal Lifter

Currently Manufacturing Models Servicing:

A320 & A220 (CSeries)

The Universal Lifter is a self-propelled hydraulic & mechanical lifting device that requires minimum maintenance. It is a two-person operation with a lifting capacity of 350 lbs. It can be fitted with a variety of specially designed Tool Heads to suit the lifting task. A set of 3 Tool Heads are sold separately; they are the Side Brace Head, Drag Brace Head, & Retract Actuator Head.

Load Test Fixtures for Universal Lifter Tool Heads (A320)

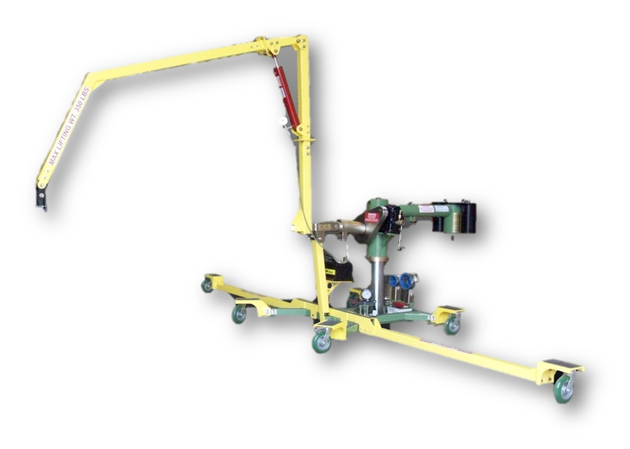

17' Flight Control Attachment (Previously Known as the 17' Boom Hoist)

For Flight Controls

Flight Control Attachment in Use:

Thrust Reverser Lifting Accessories

& Nose Cowl Sling with Cart

Power Wash Cart

Two-Man Power Wash Cart

Wheel & Tire Dolly

C-130 APU Lifting Tool

Available Services:

|

|

Keywords Related to D-Check Products:

|

|